Stainless Steel Hopper Spreader

- Capacity: 1.5 - 5.0 cu yd

- Available body side lengths: 7', 8' and 9'

- Trucks, Flatbed/Dump trucks

- Materials: Salt & Sand

- Spread Pattern: Broadcast

Product #: NA

LOWEST SHIPPED PRICE IN THE COUNTRY

Right tool for the job

It's your job to make sure the world keeps moving... and to do that, you need ice control equipment you can rely on. The all-new MARAUDER stainless steel hopper lineup is engineered to get the job done right. Choose the best material delivery system for your operation based on the de-icer you commonly use... either the all-new HELIXX shaftless auger for precise rock salt application or the pintle chain conveyor that's perfect for thick, heavy de-icing materials. Whatever choice you make, you’ll get the delivery performance you demand.

UNIQUE FEATURES

Helixx Auger Technology

- Patent-pending corkscrew material delivery system is optimized to operate in the target range for rock salt spreading best practices. The auger has multiple pitches to help promote smooth, even material flow from the hopper and prevents bridging. The shaftless technology reduces drag on the motor and reduces the overall load on the electrical system.

* Auger Models Only (S150A, S220A, S300A, S400A, S500A)

Pintle Chain Conveyor

- The large conveyor delivers reliable, smooth, and consistent material flow for heavy, dense materials while reducing bridging.

* Chain Models Only (S150C, S220C, S300C, S400C, S500C)

Hopper Construction

- The hopper is made from corrosion-resistant stainless steel and constructed entirely of rivets and bolts, with no welding. This provides a cleaner stainless look and is easier to repair for long-life and protection against stress.

Extended Material Delivery & Pre-Wet Chamber

- A material delivery extension reduces leaking/spilling during transport. This provides a more cab forward design, allowing for added stability and weight distribution of the hopper.

- When equipped with the optional pre-wet accessory, it leads into the patented pre-wet mixing chamber.

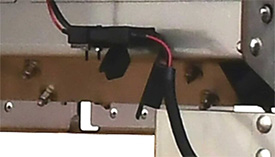

Wiring Channel For Ease of Install

- Channels on either side of the hopper allow wires and cables to be easily run from the hopper to the cab for a clean installation.

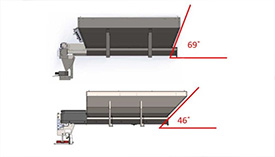

Steeper End Caps

- The end caps are at more of an angle to provide better material flow so the hopper load can be evenly spread with each fill.

Chute Design

- Baffles within the chute deliver a consistent spread pattern that reduces material waste. By directing material to precise points on the spinner, it helps to cast it away from the truck rather than onto the back of your bumper. A direct drive motor offers better torque and reduces servicing.

Chute Assembly

- For precise material application, the chute assembly can be configured for either pickup truck or flatbed and dump body applications, ensuring you're always spreading at the optimum height. An extended chute is standard on 3.0, 4.0, and 5.0 cu yd models. Sold separately for 1.5 and 2.2 cu yd models.

- The ergonomic, hinged design opens from the driver's side and swings to the passenger side, providing easy access for maintenance or material unloading. For convenient access to the hitch, the chute assembly can be removed.

Chute Power Plug

- Heavy-duty, weather resistant plug is IP-68 rated. Positive latching ensures a secure connection, even with vibrations caused by consistent travel. The plug has been tested to 5,000 mating cycles for durability for many winter seasons to come.

Spinner Channels & Spread Pattern

- An extra-large 16" polyurethane spinner delivers a broadcast spread pattern of up to 36' for salt and 24' for sand and provides long-lasting, corrosion-free performance. The ridges on the spinner ensure an even distribution of material throughout the spread arc.

Inverted V

- Reduce heavy startup loads on the drivetrain and potential bridging during operations with the optional inverted V. Made of 12 gauge 201 stainless steel, the inverted V is strong and corrosion resistant, for use in highly demanding environments. The inverted V is easy to assemble and install and will provide years of trouble free use.

- * Only accessory for 1.5 & 2.2 cu yd Chain Models (S150C & S220C)

- * Standard on 1.5 & 2.2 cu yd Auger Models. (S150A & S220A)

- * Standard on 3.0, 4.0 & 5.0 cu yd Chain & Auger Models. (S300C, S300A, S400C, S400A, S500C & S500A)

Material Spill Protector (Chain Only)

- A protection flap at the end of the conveyor prevents material from spilling out and pooling near the vehicle cab.

*Chain Models Only (S150C, S220C, S300C, S400C, S500C)

Adjustable Feed Gate

- An adjustable feed gate controls the amount of material flowing from the hopper to the spinner to regulate material flow.

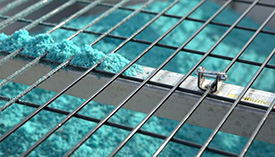

Top Screen & Replaceable Anchor

- A steel top screen comes standard, which helps break up large chunks of de-icing material during the loading process to prevent clogging and bridging during spreader operation. The anchor piece is now bolted on instead of welded for easy replacement.

Specifications

Affordable financing programs for Western, Fisher SnowEx, SaltDogg and SnowWolf Snow Plows and Salt and Sand Spreaders, designed for In-State and Out-of-State residence.

Contact us for more information on all these finance options, 309-662-5344.

*Customer must be present in Bloomington, IL to complete financing and take delivery of Product.

90 Days Deferred Payment

COMMERCIAL PROGRAM DETAILS

CONSUMER PROGRAM DETAILS

Application for Credit

Local/In-State Residence

Please complete and submit the application online. Please click here.

After application is approved, must be able to provide a signiture in person at our location.

First Choice for Snow Plow Professionals

For over 60 years WESTERN® has been leading the plow industry by providing top-quality snowplows and ice control equipment. For more than six decades the WESTERN brand has been the first choice for snow plow professionals with revolutionary technology, expertise in the plowing industry and state of the art manufacturing capabilities.

Located in Milwaukee, Wisconsin, WESTERN is the leading manufacturer of CONTRACTOR GRADE® plows. WESTERN offers snow equipment for heavy-duty and standard-duty commercial snow plowing, institutional, extended-use homeowner and municipal snow removal operations. We have a full line of snow plows, and a variety of hopper and tailgate-mounted ice control sand and salt spreaders, in addition to our full line of snow plow parts and snow plow accessories

Leaders in the Snow Plowing Industry

The focus at WESTERN is to build equipment that helps our customers succeed and give them a competitive edge in the market. As leaders in the snow plowing industry we are at the forefront of changing technology, to better meet our customers needs and wants. WESTERN stays in touch and in tune with our customers to develop solutions and deliver snow equipment that gets the job done right, the first time! As part of a lean manufacturing strategy, WESTERN is able to react quickly to changing requirements and customer needs. WESTERN also proactively pursues environmental responsibility throughout the manufacturing and procurement process, voluntarily making sustained efforts to exceed compliance requirements.