The low-maintenance, rust-resistant STEEL-CASTER stainless steel hopper spreader was designed to maximize material control and minimize waste.

- Capacity: 1.5 - 6.0 cu yd

- Material: Salt & Sand

- Spread Pattern: Broadcast

Product #: NA

LOWEST SHIPPED PRICE IN THE COUNTRY

Engineered to Own the Ice

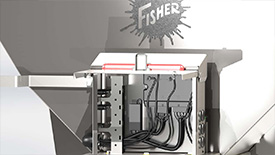

The FISHER STEEL-CASTER stainless steel hopper spreaders were designed for efficiency and engineered for durability. Built with the experience of more than six decades of battling tough New England storms, the STEEL-CASTER hopper spreaders are available in six sizes, with more standard features and the latest advancements in technology, resulting in maximum material control and minimal waste.

UNIQUE FEATURES

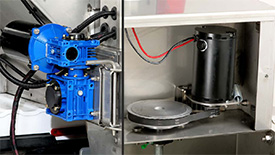

Dual Electric Motors

The two high-torque 12-volt electric motors provide quiet, reliable and independent control over the conveyor and spinner mechanisms. The spinner motor is sealed inside a weather-resistant housing, protecting it from corrosion, while the conveyor motor is completely sealed from the elements.

*Gas and hydraulic options also available.

Hydraulic Powers

The STEEL-CASTER stainless steel hopper spreader is available with hydraulic power. With the most available power in its class, the hydraulic powered motor option offers dual variable speed control and reliable operation.

Controls

Dual Electric Motor Control

- Enhanced dual variable-speed control allows you to precisely match material delivery and spread patterns to conditions.

- Four standard accessory buttons and a dedicated blast button provide optimum in-cab efficiency.

- Easy-to-understand, digital self-diagnostics alert the operator when the spreader is empty or when adjustments are needed, and LEDs make the control easy to read.

- Its compact size compared to traditional controls fits easily into today's modern truck cab designs.

Innovative Chute Design

Baffles within the chute deliver a consistent spread pattern that reduces material waste. By directing material to precise points on the spinner, it helps to cast it away from the truck rather than onto the back of your bumper.

Corrosion-Resistant Hopper

Constructed from maintenance-free, corrosion-resistant stainless steel, the hopper is reinforced with welded joints, which wrap around for long-life and protection against stress.

Shutter Deflector

The easy-to-adjust circular shutter deflector allows directional spreading, providing optimal material control, while maintaining even coverage.

Material Delivery

One of the widest in the industry, the 16 1/2" pintle chain conveyor moves more material consistently and smoothly to help reduce bridging. Corrosion-resistant stainless steel guides provides extra protection and durability.

Spinner

An extra large 15 1/2" polyurethane spinner delivers a spread pattern of up to 40' and provides long-lasting, corrosion-free performance.

Accessory Integration

Conveniently connect accessories directly into the hub mounted in the back of the hopper. Accessories automatically integrate with the hopper control without having to run additional wires from the front of the truck.

*Feature available on dual electric motor models only.

Dump & Work Light Switches

Operators can safely offload material or fill walk-behind spreaders by using the rear mounted conveyor dump switches. A third switch is also provided so that an accessory work light my be conveniently controled from not only the cab but also the rear of the hopper.

*Feature available on dual electric motor models only.

Dual Swing Chute

The dual swing chute design opens from either side to provide easy access for maintenance or material unloading.

Chute Assembly

- For precise material application, the chute assembly can be configured for either pickup truck or flatbed and dump body applications, ensuring you're always spreading at the optimum height. An extended chute is standard on 9' and 10' models. An extension kit is available as an accessory only on 7' and 8' models.

- For convenient access to the hitch, the chute assembly can be removed.

Adjustable Feed Gate

An adjustable feed gate provides additional control of material flow regardless of material type, reducing waste when traveling between sites.

Inverted V / Vibrator

- An inverted V comes standard and helps keep sufficient material weight off of the conveyor, ensuring smooth startup and flow of material.

- A vibrator kit is available as an accessory to help reduce bridging and keep material moving smoothly to the conveyor.

Top Screen

A steel top screen comes standard, which helps break up large chunks of de-icing material during the loading process to prevent clogging and bridging during spreader operation.

Ratchet Straps

Ratchet straps are provided standard for additional spreader stability. A chain tie-down kit is available as an accessory.

Additional Standard Features

Tie-down points are included for strapping the hopper to the truck. For additional safety, bolting bars are also provided to attach the hopper to the vehicle and a Center High-Mounted Stop Light (CHMSL) is standard.

FLEET FLEX

- The STEEL-CASTER hopper spreader is designed with FLEET FLEX technology for easy interchangeability between electric hopper spreaders without having to change the wiring or the controls.

- It provides easy operation, increased reliability, simple wiring and easy installation.

- Additonally, accessories automatically integrate into the control for easy plug 'n play.

*Feature available on dual electric motor models only.

Specifications

![]() Fisher Steel-Caster Owners Manual

Fisher Steel-Caster Owners Manual

![]() Fisher Steel-Caster Installation

Fisher Steel-Caster Installation

Affordable financing programs for Western, Fisher SnowEx, SaltDogg and SnowWolf Snow Plows and Salt and Sand Spreaders, designed for In-State and Out-of-State residence.

Contact us for more information on all these finance options, 309-662-5344.

*Customer must be present in Bloomington, IL to complete financing and take delivery of Product.

90 Days Deferred Payment

COMMERCIAL PROGRAM DETAILS

CONSUMER PROGRAM DETAILS

Application for Credit

Local/In-State Residence

Please complete and submit the application online. Please click here.

After application is approved, must be able to provide a signiture in person at our location.

Delivering Quality and Service to the Plowing Industry for over 60 Years

Dedication to quality and service has been a FISHER tradition from the start. A proven and a trusted company, Fisher Engineering has been producing snow plows for over 60 years in the coastal city of Rockland, Maine. Through the years our plowing equipment has earned us a solid reputation for reliability and strength, especially among commercial snow plow professionals.

Whether you’re a homeowner, small business owner, professional snowplower or municipality, Fisher Engineering has a snowplow to fit your needs. We offer snow plows that are built to withstand the rigors of any commercial application as well as personal snow plows for smaller and lighter four-wheel-drive vehicles. To help you find the perfect snow plow for your truck use our eMatch system. Whatever your snow removal needs, Fisher Engineering has the right snow equipment to help you get the job done.

Our focus is on our customers; we work hard to manufacture innovative products that give our customers an edge in the market. Timely service to our customers has always been, and will continue to be, a hallmark of our company.

A Partner in Snow Removal

We’re proud of our products and confident that your investment in FISHER snow plows and ice removal equipment will pay dividends for years to come. Fisher Engineering offers a wide range of snow and ice control equipment for the professional snow plower. From rugged straight-blades, to hard-working V-plows and a versatile expanding-moldboard model, Fisher Engineering offers high-capacity solutions for every plowing need. A full line of tailgate and hopper salt and sand spreaders completes the snow and ice control equipment product offering.

As a market leader, Fisher Engineering believes it is important to proactively pursue environmentally responsible policies and procedures, not only internally but also throughout our extended supply chain.